Protect your cylinder investment with Western’s cylinder services . Western’s cylinder testing facilities utilize a proprietary software system that incorporates an exhaustive database of DOT and TC standards, CGA guidelines and customer specific test requirements. In addition, the Western system maintains a permanent record of cylinder specific information and allows you the ability to provide individualized instructions to your particular requirements. With the touch of a button all plant locations can be updated with new information as it becomes available reducing the chance of errors or omissions in the testing process. The software is compatible with either the UT or hydro-test methods.

- Requalification

- Hydro-test

- Ultrasonic testing

- Valve and safety services

- Internal cleaning

- Neckring services

- Painting

- Special handling services

- Disposal of cylinders

Click here for more information on cylinder testing

Cylinder Hydrostatic Testing

Western International provides superior, technology driven solutions for the hydro-testing of your cylinders.

Our patented and highly effective hydro-testing system uses patented analysis tracking software to capture and maintain information in our computerized databases. This proprietary system increases testing precision and allows for the processing of exemptions while simultaneously providing accurate, up-to-date documentation to meet CGA and DOT guidelines.

Western’s hydro-testing system is dramatically different from any other system available on the market. Employing an array of effective functions, the advanced programming is designed to eliminate operator errors and cut down labor expenses.

Cylinder Requalification

At Western International, highly trained personnel use a semi-automated process to perform DOT required low-pressure cylinder requalification of both acetylene and propane cylinders.

Hands-on training and classroom studies equip our employees to provide exceptional service and maintenance for cylinders based on DOT regulations, CGA guidelines and our own stringent internal procedures.

Cylinder Maintenance

Our automated testing and maintenance processes incorporate the newest technologies to enhance the efficiency and quality of every product. Cylinder maintenance programs include state-of-the-art services, and an array of related services, including:

- Shot blasting

- Painting

- Internal and external cleaning

- Inspection

- Neckring replacement

- Disposal of condemned cylinders

- Cylinder gas conversion

Custom painting and stamping are available upon request. All paint and refinishing procedures are performed in accordance with EPA and OSHA guidelines.

Cylinder Filling

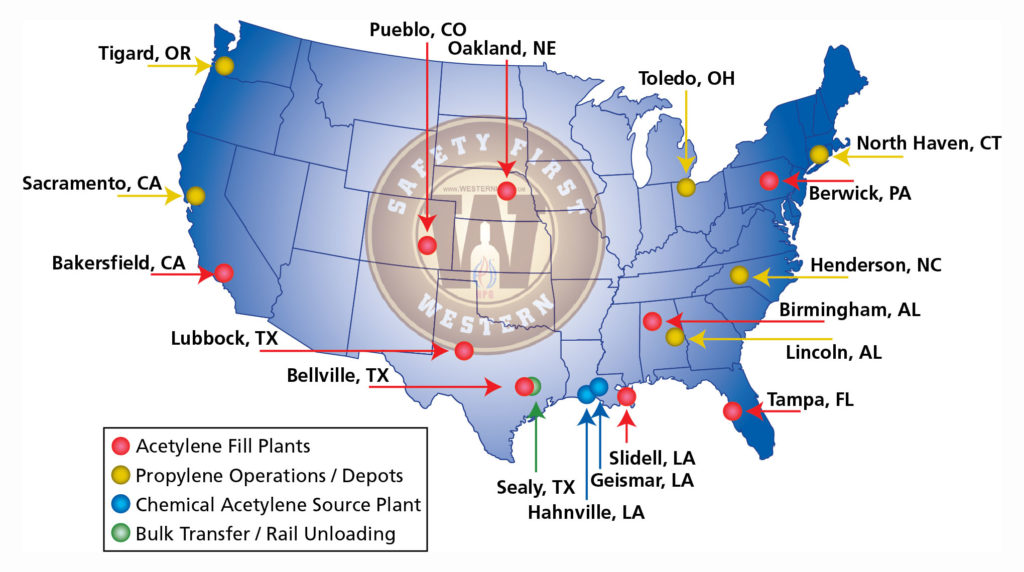

Western’s U.S. Footprint

Western International’s multiple cylinder fill plants and bulk fill operations are across the United States. Our concentration on acetylene as a core product makes us a strong partner in controlling quality and cost to our customers.