Chemical Synthesis

Chemical manufacturers are able to reconsider acetylene as a specialty feedstock. Chemical applications using bulk-supplied acetylene are becoming increasingly common now that modernized bulk delivery solutions have resolved previous cost and supply chain issues.

The reactivity of acetylene makes it ideal for the manufacture of vitamins, pharmaceuticals, intermediates for nitrile rubbers, acrylic fibers, insecticides, food flavorings, cosmetics, perfumes and solvents.

Mold Release

Acetylene is the most economical fuel gas when oxygen usage, labor and the quality of work outcomes are taken into consideration. It also produces the highest flame temperature of any fuel gas, releasing large amounts of carbon when carburized to effectively lubricate glass molds for easy release.

Vacuum Carburizing

Acetylene and acetylene-based mixtures have become the preferred choice for use in the vacuum carburizing process. Acetylene is a catalytically decomposable hydrocarbon, which essentially means that it will break down into its elemental constituents in the presence of a hot metal surface in a vacuum furnace operating at low pressure—typically at or below 10 mbar (7.5 Torr).

Other hydrocarbons (e.g., methane, propane) are thermally decomposable, which means that they will break down immediately upon entry into the hot zone of the vacuum furnace, negating the ability of the carbon to react with the surface of the steel and creating unwanted hydrocarbon byproducts.

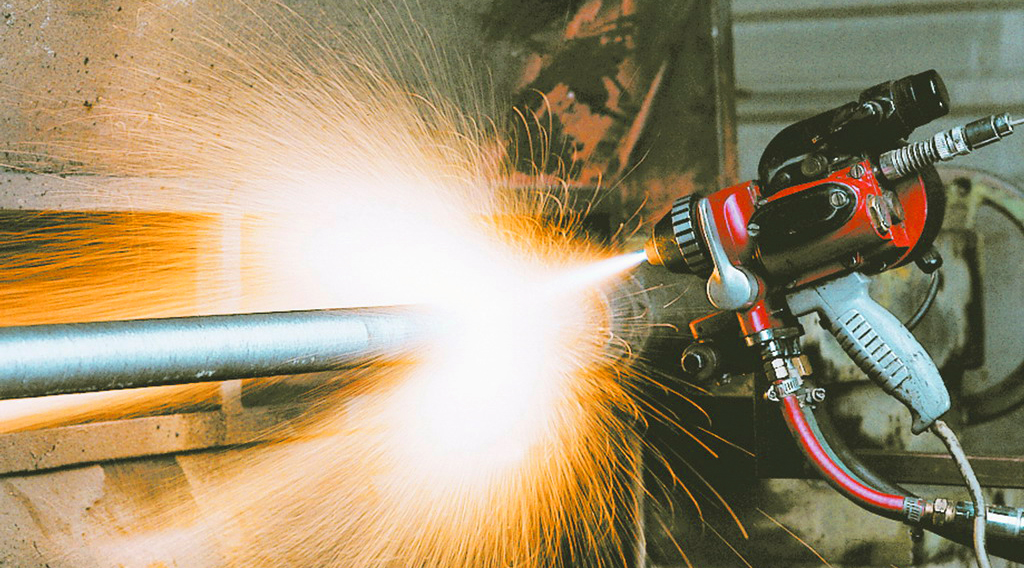

Flame Spray

In flame spray torches, a mixture of acetylene and oxygen is combusted at the front of the torch, external to the nozzle. In some designs, a constricting flow of air is fed through a concentric set of holes at the nozzle exit and is used to pinch the expanding gases, generating a higher temperature combustion zone. It uses the basic principles of a welding torch with the addition of a high velocity air stream to propel molten particles onto the substrate.

Bulk Acetylene Oxy-Fuel Cutting and Welding

Bulk acetylene supply provides significant savings to customers engaged in oxy-fuel cutting and welding applications. After analyzing economic studies of bulk machine cutting, findings show that acetylene pricing has been based upon single cylinder costs, rather than bulk acetylene costs. Once bulk acetylene costs are applied to economic comparison studies, acetylene competes well with secondary fuel systems.

For larger bulk applications, Western provides trailers with the capacity to carry more than 100,000 cubic feet of acetylene. Visit acetylene page for more information.

Single Cylinder Oxy-Fuel Cutting and Welding

Acetylene has maintained a dominant position in this market, and for good reason. For cutting and welding, acetylene offers a safer, more efficient solution with a better return on investment than that of any other gas.

In relation to Oxy-fuel cutting, the properties of cylinder acetylene make it a highly effective tool. When compared with other gases, such as propane, users are able to perform faster and for extended periods of time with acetylene.